A ceramic capacitor ceramic capacitors are typically referred to as disc capacitors they re made by taking a small ceramic or porcelain disc and coating both sides with silver before stacking them together to make a functioning capacitor.

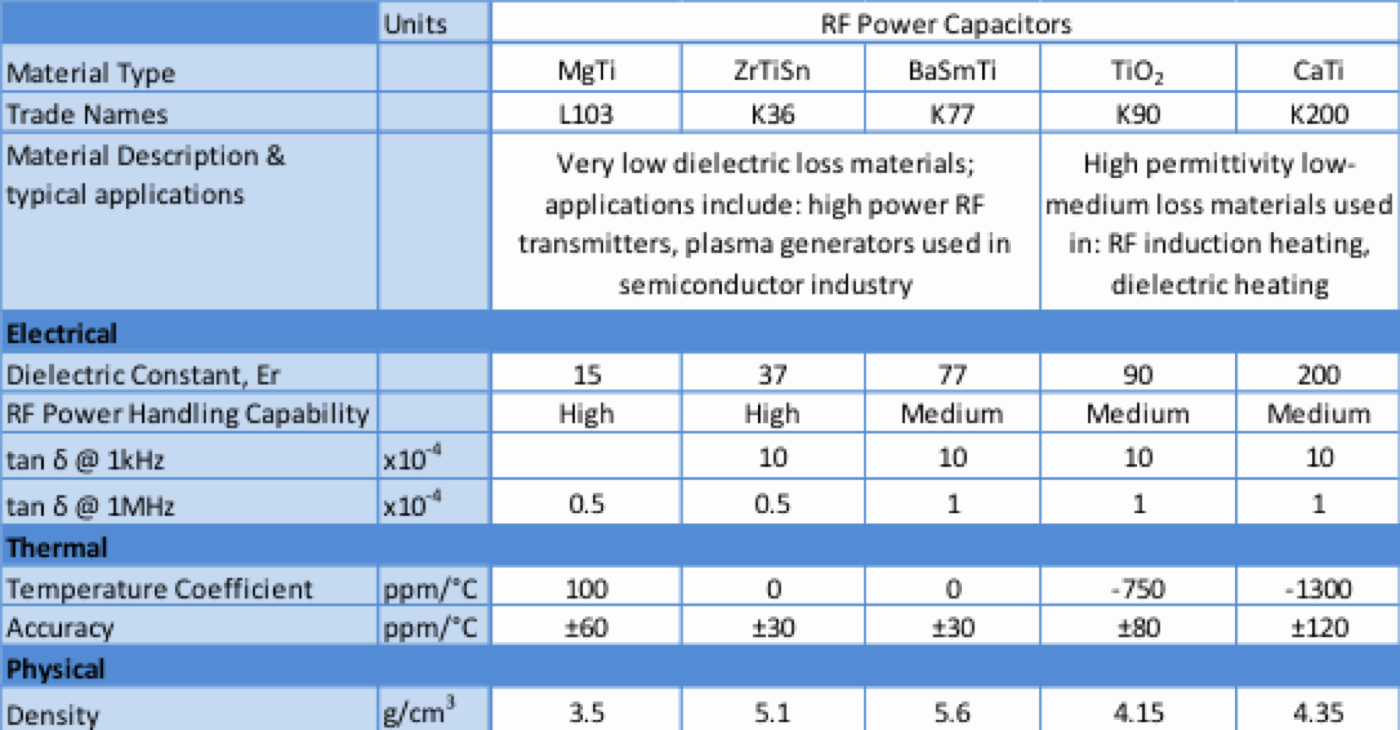

Different ceramic capacitor formulations.

I ve done laboratory testing of ceramic capacitor for microphonics and found that you need to really smack them with high impact.

Based on the type of the material used the ceramic capacitor is classified as class1 class2 class3.

The values of the ceramic capacitors are typically between the 1nf and 1µf and the values are up to 100µf are possible.

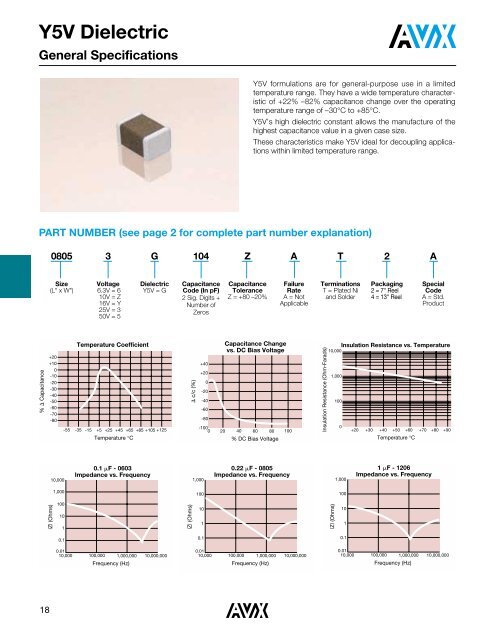

Class 2 ceramic capacitors offer high volumetric efficiency for buffer by pass and coupling applications.

Modern c0g np0 formulations contain neodymium samarium and other rare earth oxides.

C0g np0 ceramics offer one of the most stable capacitor dielectrics available.

The decline in capacitance is called aging and occurs at a rate that decreases roughly linearly with the log of time.

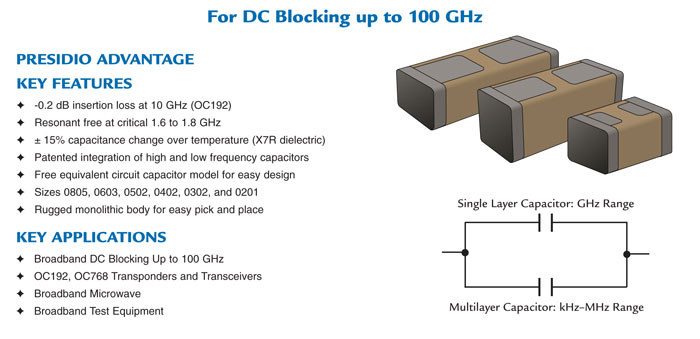

The two common types of ceramic capacitors are multilayer ceramic capacitor mlcc and ceramic disc capacitor.

Due to its low permittivity c0g ceramic capacitors have low capacitance.

This ceramic dielectric material has low relative permittivity.

Class3 uses a semiconductor material which is hardly in use nowadays.

Capacitance change with temperature is 0 30ppm c which is less than 0 3 c from 55 c to 125 c.

Ferro s lcf series formulations are co fireable with 100 ag 95 ag 5pd and 90 ag 10pd conductors.

Rmc was a popular brand years ago and made lots and lots of different kinds of caps.

These have poor temperature and voltage coefficients.

Ceramic capacitors are divided into two application classes.

Interestingly the c0g capacitors have a different formulation which does not display any aging characteristic.

C0g also commonly known as np0 is an ultra stable dielectric material.

C0g np0 is the most popular formulation of the temperature compensating eia class i ceramic materials.

Multilayer ceramic capacitors having improved end metallization coatings comprising fired on silver frit coatings contacting the internal electrodes exposed at each end of the capacitor and extending over onto a side face thereof to form two spaced apart bonding pads and thin electroplated copper coatings conformally covering the silver coatings.

The class2 capacitors which uses ferroelectric material is more preferred nowadays compared to the class1 capacitors which uses a paraelectric material.

The z5u tempco is about the least stable of the ceramic formulations.

I discussed reliability issues with an engineers from.

The multilayer ceramic capacitors are prepared by using the surface mounted smd technology and they are smaller in size therefore it is used widely.

Single ceramic discs of around 3 6mm are used when low capacitance values are needed.

Our low temperature ceramic formulations include lcf mid k and lcf high k formulations designed for passive electronic component applications that include esd emi filters multilayer ceramic capacitor mlcc and single layer chip slc components.