Smd capacitor one of the derivatives of smt surface mount technology having small and easy to place components which enhances the manufacturing speed.

Different types of smd capacitors.

As a result of the different construction and requirements for tantalum smt capacitors there are some different packages that are used for them.

In contrast to ceramic film and electrolytic capacitors supercapacitors also known as electrical double layer capacitors edlc or ultracapacitors do not have a conventional dielectric.

One example is that is smd inductors.

Some of them are polarized.

The core difference between these capacitors types is the material used as a dielectric and dielectric should be chosen properly according to their properties.

Separate pages have been devoted to the different dielectric technologies but this page provides a summary of the specific surface mount capacitor details.

The positive terminal for the polarized ones is marked.

The different types of smd capacitors are multi layer ceramic smd capacitors tantalum smd capacitors electrolytic smd capacitors etc.

Naturally it is very difficult for the very smallest sizes but smd inductors are available in 0805 and 0603 sizes.

There are many different types of smd capacitor ranging from ceramic types through tantalum varieties to electrolytics and more.

Sometimes the term smd referred to as smt surface mounted technology.

This capacitor designing can be done including two leads so that placing of these components on pcbs is so easy.

The smd technology manufacturer s capacitors easily so that bulk manufacturing can be done easily.

A multilayer ceramic smd capacitor consists of many rectangular block of dielectric in which a number of electrodes are contained.

These capacitors are rated according to the ceramic electrical properties.

The electrical property of ceramic is multi dimensional.

So the capacitor like smd can be designed with different technology.

Smd technology and they are.

The picture shows smd type capacitors.

Another type the electrochemical capacitor makes use of two other storage principles to store electric energy.

These are placed on pcb by pick and place machine.

Use of ceramic significantly reduces the size of smd capacitor compared to other types of capacitors.

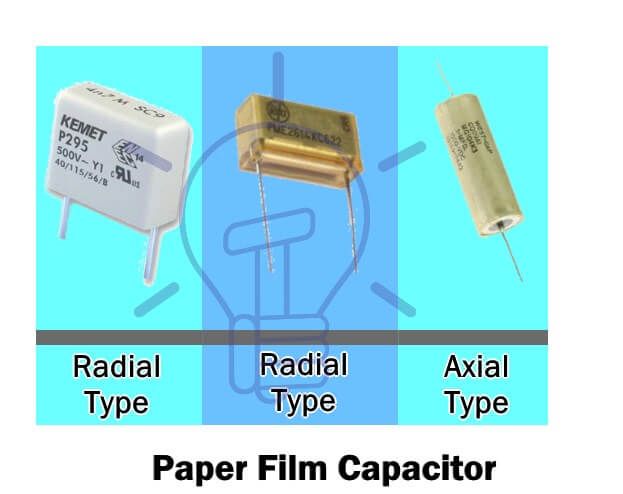

There are different types of film capacitors are available like polyester film metallized film polypropylene film pte film and polystyrene film.

Of these the ceramic smd capacitors are the most widely used.

It is a type of capacitor in which ceramic is used as dielectric matter.

Smd capacitors are manufactured in stripes as shown in figure.

They have values up to 10µf.

These are seen in embedded circuits.

Ceramic tantalum electrolytic capacitors are few of the available options when it comes to smd capacitor.

The capacitance value of an electrochemical capacitor is determined by two high.