Due to their prominent properties mechanical stiffness strength thermal stability ceramic composite materials cmc have been widely applied in automotive industrial and aerospace engineering as well as in biomedical and electronic devices.

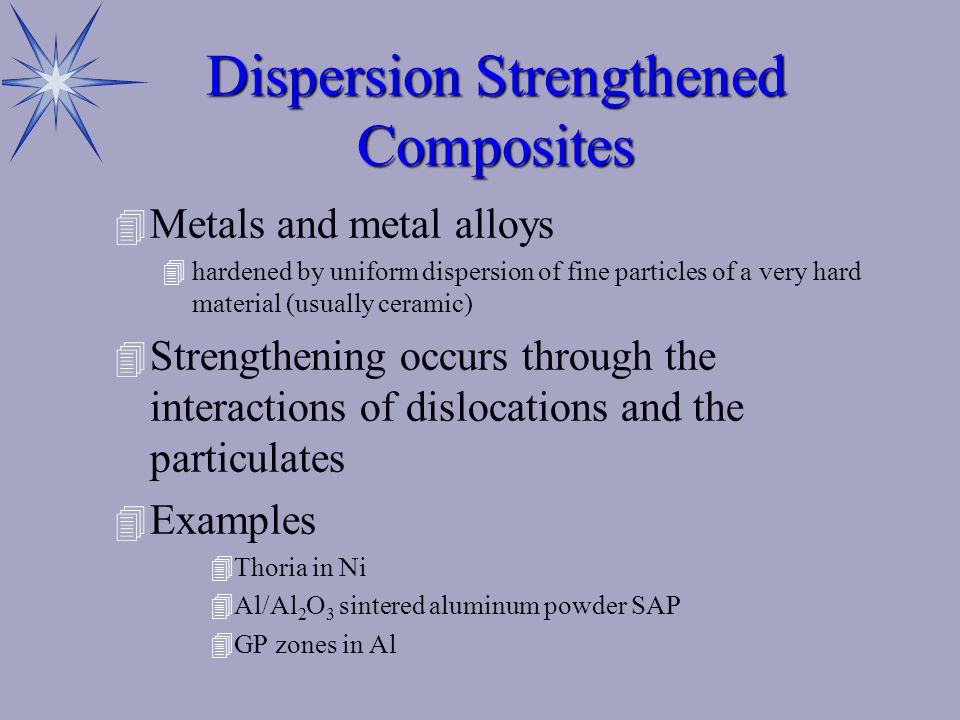

Dispersion strengthening ceramics.

Moderate strengthening of dental ceramics can be achieved with appropriate fillers added and uniformly dispersed throughout the glass.

Reduction of tensile stresses metal tooth advanced ceramic core dispersion strengthening bonding to 12.

Previous explanations of strengthening of glass ceramics after heat treatment to produce crystallization are discussed.

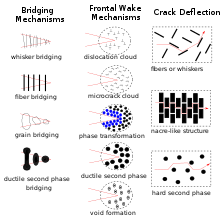

The approaches in strengthening ceramics are as follows.

Production of prestressed surface layers in dental porcelain via ion exchange thermal tempering.

Ceramics ceramic solution pre increasing prior art date 2012 12 22 application number dk13823937 1t other languages danish da inventor konrad kampfer denis elmazi original assignee metoxit ag priority date the priority date is an assumption and is not a legal conclusion.

Therefore difficulty in the cooling rate control is one of disadvantages of thermal strengthening method.

The effect of dispersion strengthening is effective at high temperatures whereas precipitation strengthening from heat treatments are typically limited to temperatures much lower than the melting temperature of the material.

Controlled crystallization of glasses 6.

Dispersion strengthening of glasses 4.

Explanations relating strength enhancement in brittle material systems either to flaw size limitation by interparticle spacing or.

Because monolithic ceramics exhibit brittle behaviour and low electrical conductivity cmcs have been greatly improved in the last decade.

Ceramics such as those based on zirconia are likely to undergo phase transformation in particular the yttria stabilized zirconia which is associated with strengthening of the material.

Request pdf dispersion strengthened glass matrices glass ceramics a case in point previous explanations of strengthening of glass ceramics after heat treatment to produce crystallization are.

The copper matrix composites hereinafter called cmcs are usually prepared by the addition of fine dispersed ceramic particles to the copper matrix.

Strengthen with a metal substructure 3.

In amorphous materials such as polymers amorphous ceramics glass and amorphous metals.